The Proceedings of the IMechE, Part D: Journal of Automobile Engineering has published a new article of mine, entitled Modelling and Experimental Validation of the Performance of a Digital Displacement® Hydraulic Hybrid Truck. I did this work in partnership with Danfoss. The paper is open-access and freely downloadable.

Paper Overview (TL;DR)

We added hydraulic hybridisation to a light truck and improved its fuel economy by 23%. We also used simulation to show that hydraulic hybridisation can improve the fuel economy by up to 95%, depending on the type of driving

Motivation

My previous work has shown that hydraulic hybridisation is effective at reducing the fuel consumption of heavy goods vehicles. However, this research was limited due to the hardware used and wasn’t tested in a controlled environment (on a rolling road, or ‘dynamometer‘).

In this work, Danfoss converted a light truck to a hydraulic hybrid using their Digital Displacement® technology, and tested it on a dynamometer.

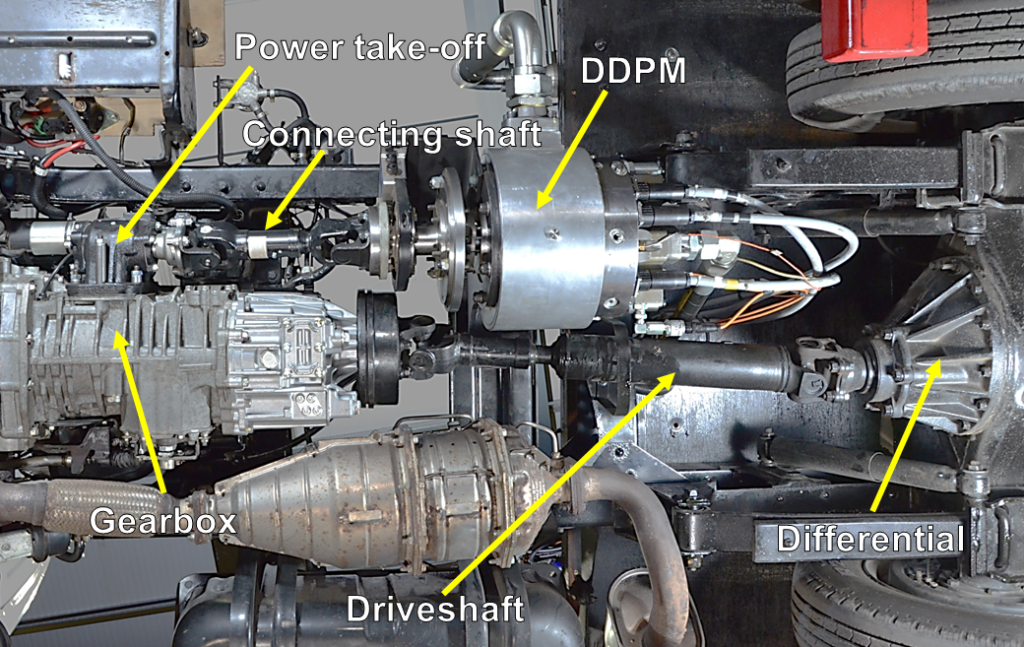

The Vehicle Conversion

Danfoss converted a light truck to a hydraulic hybrid using a Digital Displacement® pump/motor. (A pump/motor can produce negative [braking] torque and a positive [accelerating] torque, rather than just one or the other.) The system stores recovered energy in a high-pressure hydraulic accumulator.

Test Results

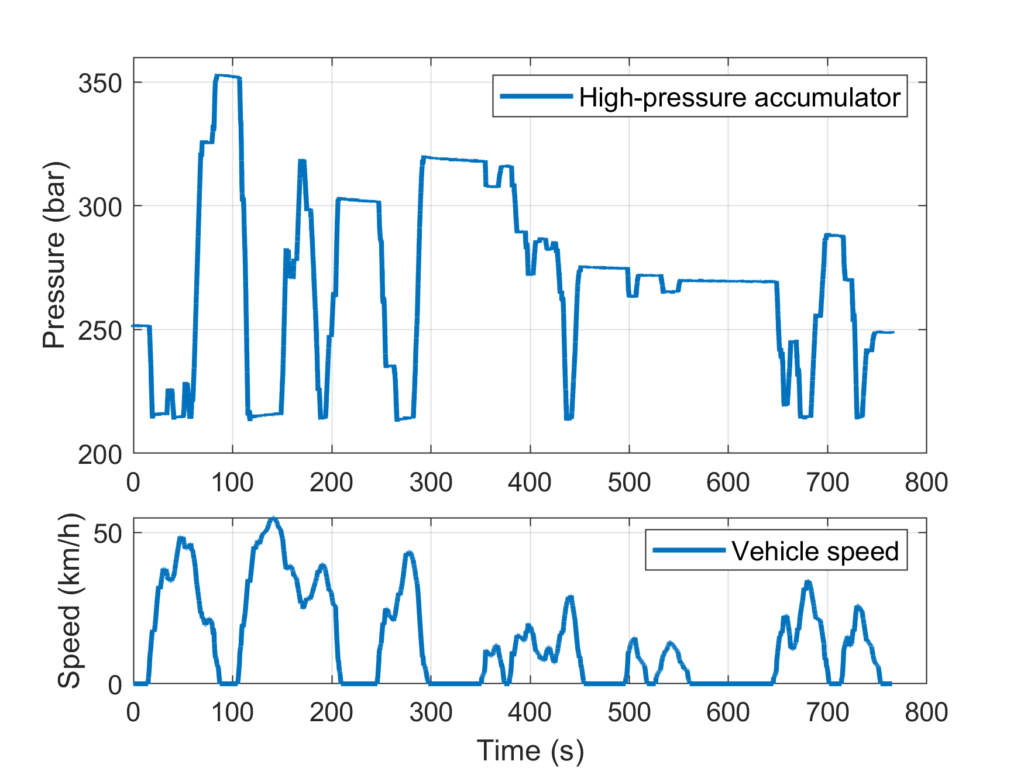

First, we checked to see how consistent the drivers were. They were remarkably consistent; the distance covered in the tests had a standard deviation of 0.3%! After that, we checked the results from the logging equipment to make sure it was sensible.

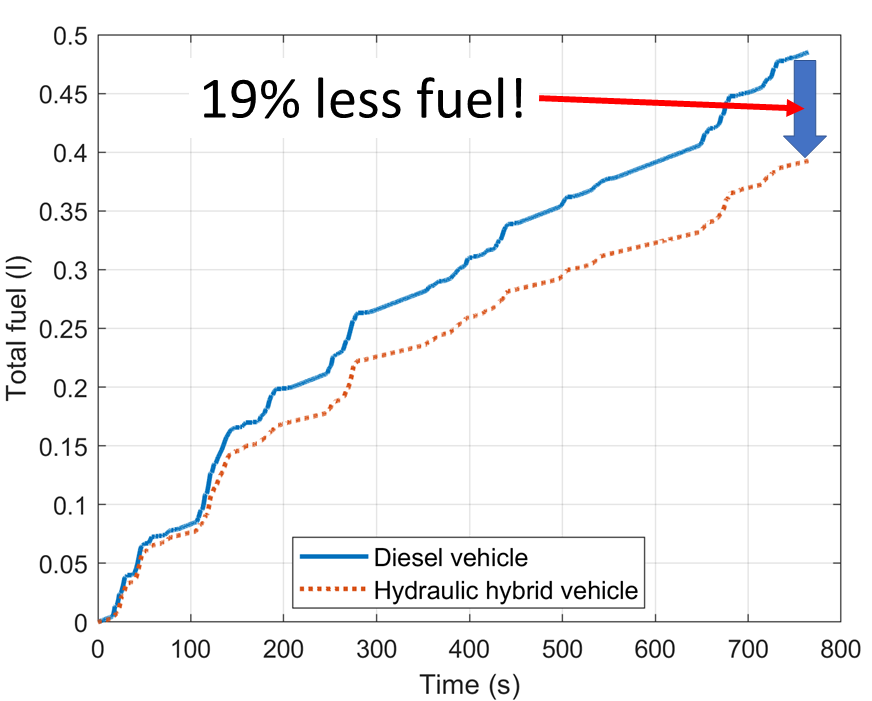

Next, we looked at how the fuel usage of the hybrid vehicle compared to the un-altered vehicle. (Hint: it used a lot less fuel!)

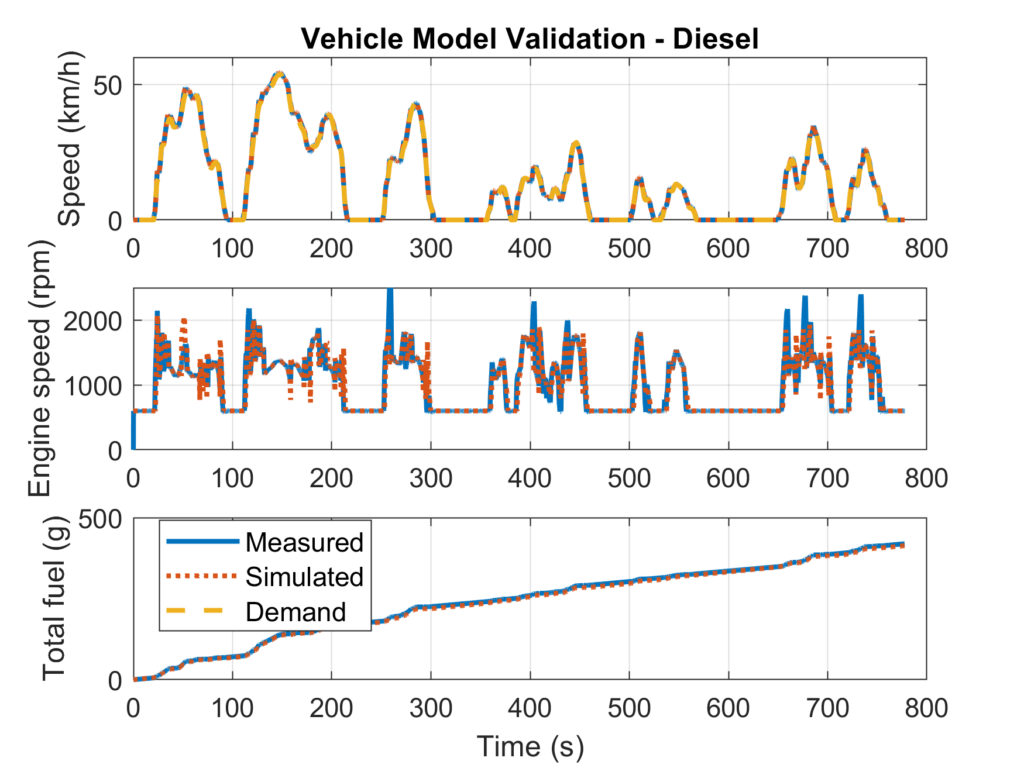

Model Validation

After that, we checked to make sure our model was a reasonable fit with the experimental data .(This step is called ‘validation‘, and is a common technique in engineering.)

Model Performance

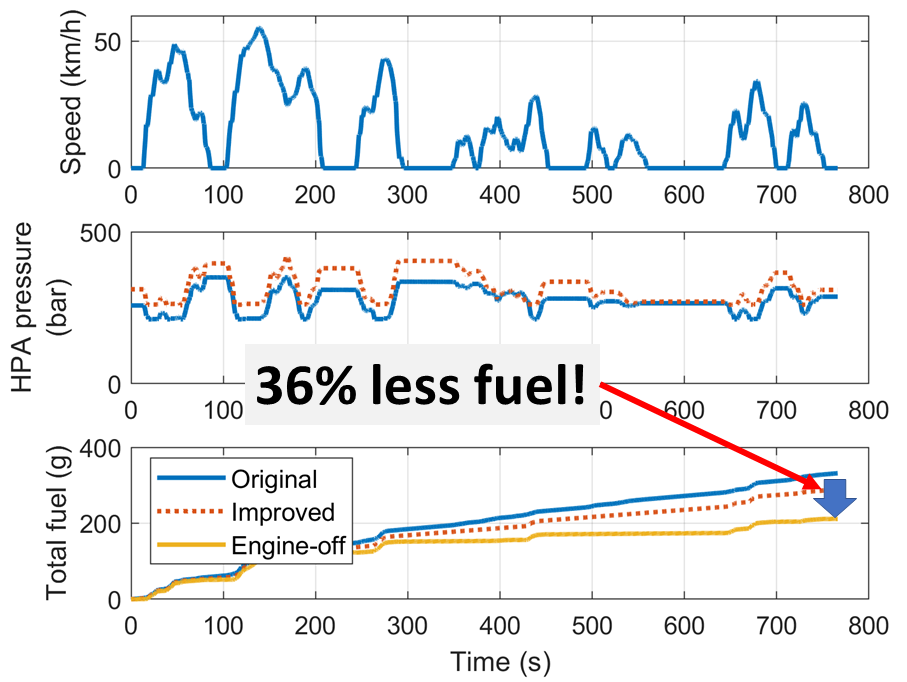

Now that we had a working model, the next step was to use this model to investigate what benefits might be achievable if we could change some of the system parameters. We found that with some small parameter changes, and by turning off the engine when it wasn’t being used, the vehicle would use much less fuel. It used 36% less fuel over this cycle!

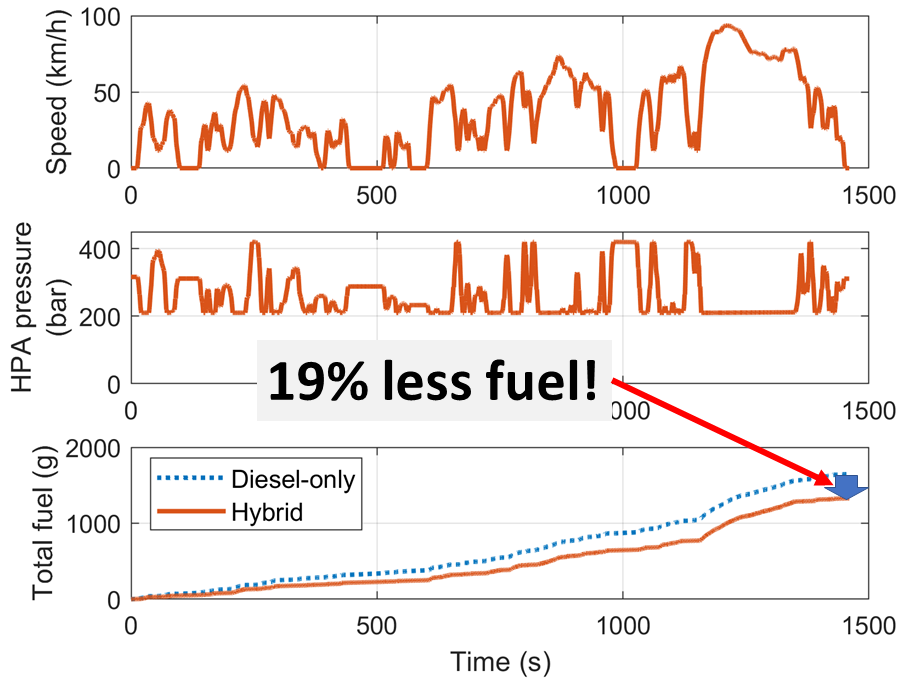

Next, we looked at the performance on a more common drive cycle, the WLTP cycle. In this case the hybrid truck used 19% less fuel than the original diesel vehicle – not bad!

Conclusions

The main conclusions of our paper were:

- It’s possible to use Digital Displacement technology to make a hydraulic hybrid truck.

- Hybridising the vehicle reduces fuel consumption by 19-36%, depending on the drive cycle.

If you want more information, please check out the full paper online.

There is more information on my other decarbonisation work on electric vehicles and rail vehicles as well.